Coatings with Vacumat® technology

The Vacumat application method is especially suited for the fast and precise application of 100% UV coating materials and water-soluble glaze systems. This innovative technology is the ideal solution for the even and/or partial application of varnish.

The decision for a coating product and the related application process needs to be carefully considered. With the vacumat technology, you increase the efficiency of the coating process, optimise series production and save time and costs.

Vacuum coating is used, among other things, in the furniture, door and wood construction industries, the flooring sector or in window coating:

Advantages of ADLER coatings with the Vacumat®

- Fast and efficient coating, depending on the workpiece, feed rates of up to 50 m/min and more can be achieved

- Ideal for all-round coating, partial coating or edge coating

- Consistent production quality

- Loss- and overspray-free coating of profile elements in just one pass

- Suitable for water-based varnish, 100% UV systems, water-based UV varnish

- Coating thicknesses from 20 to 200 g/m² depending on the coating system

- Edge coating possible with special attachments

Vacumat®

This application technique is ideally suited for complete coating, partial coating or edge coating of mouldings or profiles.

ADLER tests the ideal processes for you

Since we at ADLER Coatings not only manufacture paints and varnishes, but also develop them ourselves and test them in our application technology department using the appropriate equipment, we also have reliable data for all the necessary calculations, such as density, volume, solids content, application efficiency and much more.

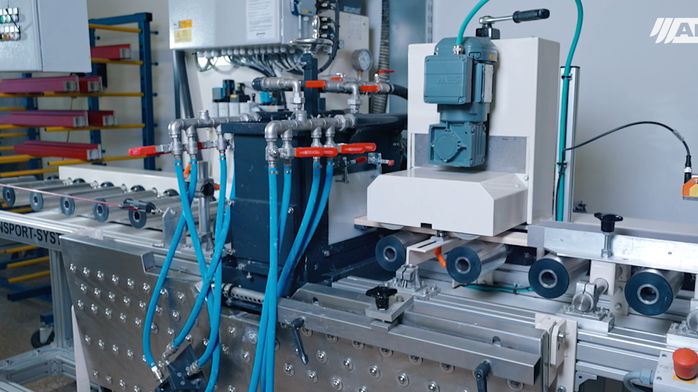

It is also important to us to support our customers optimally in the planning and adjustment of their own coating systems. That is why we have a custom-built vacuum unit in the ADLER application technology department. Our Schiele VACUMAT® has two completely separate material circuits for water and UV-100% systems. This allows us to test water-based and UV systems for our customers and share our experience.

Arrange a non-binding consultation now! Our specialists will contact you immediately. Together with our industry partners, we will tailor the entire application, including system configuration, to your needs.

Our industrial partners

© by adler-lacke.com