Avoid adhesive penetration, fading and furrier

If adhesive reaches the upper zone while veneering, the stain cannot penetrate deep or not at all...

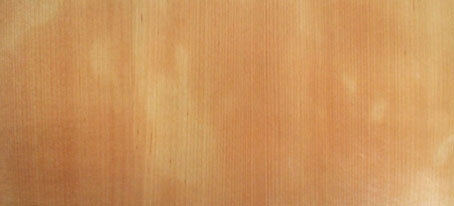

Adhesive penetration

If adhesive reaches the upper zone while veneering, the stain cannot penetrate deep or cannot penetrate at all and the appearance of the stain becomes spotted. This problem occurs particularly with medium and dark shades of stains since the adhesive penetration causes bright spots.

With natural coatings, the wetting can become non-uniform, especially when working with PUR coatings having strong grain accentuation.

Prevention:

- Avoid excessive application of adhesive - lesser quantities of application 90 – 120 gm/m².

- Do not use any low viscosity adhesives (Extenders with organic powders, e.g. rye flour, maize flour or bean flour).

- and do not use any porous or moist veneers.

Fading

Real fading is colour change that develops on account of chemical processes under very specific conditions in the wood.

They occur often by:

- Reactions (e.g. tannic acids etc.).

- Substances that are added to the wood (e.g. hardeners).

- Temperatures (very high pressing temperature and too little cooling off).

- Humidity.

- Light (UV radiation etc.).

Unreal fading refers to surface impurities caused by foreign substances that do not cause any chemical reactions:

- Dirt particles.

- Sanding dust (light and dark veneers using the same sandpaper).

- Oil and grease etc.

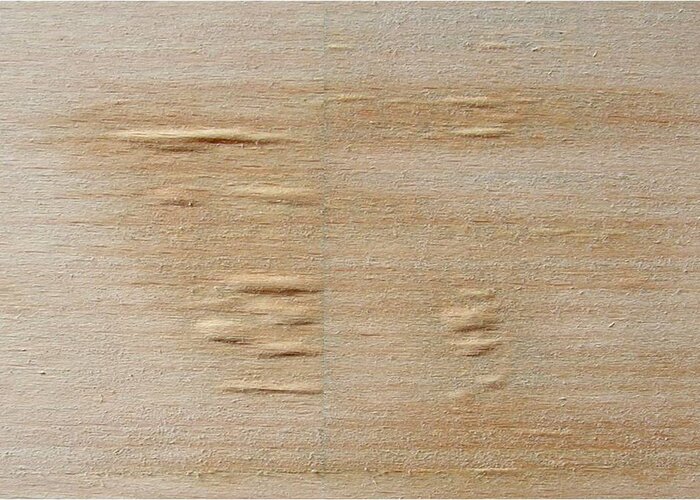

Furriers

They occur often by:

- Too little adhesive, dirt or grease on the carrier material.

- Cavity in the carrier plate.

- Defects in the veneer.

- Dirt on the carrier plate.

Removal:

- Cut up the furrier.

- Lift the veneer.

- Press the adhesive in and press the area again.

Prevention:

- The carrier material should always be calibrated and the adhesive should be applied uniformly.

© by adler-lacke.com