Surfaces that feel good with DLE plus and ADLER

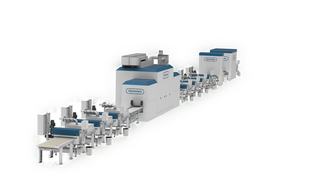

With the innovative, patented Digital Lacquer Embossing (DLE) technique, the German plant and equipment manufacturer Hymmen has expanded the possibilities of industrial surface finishing.

20 Jan 2022

With DLE, a painted or printed surface is coated with a transparent topcoat and then a fine structure is pressed into the paint before it has completely hardened. Used in combination with a high-quality coating system such as ADLER's Innolux Topcoat DLE, this technique can be used to create unique surfaces with a fascinating look and feel. Now the manufacturer of the equipment for this technique has developed it even further and, with DLE plus, they have enhanced the benefits of Digital Lacquer Embossing: DLE plus makes it possible to create embossed textures with a depth of up to 200 µm and precise, sharp edges. Furthermore, they can offer a range of different gloss levels and variable depths in order to achieve surfaces that are even more individual and more natural-looking.

Endless possibilities

Digital Lacquer Embossing makes it possible to create surface structures that will perfectly match the optical design. This opens up a diverse range of possible areas of use, as Daniel Pesserer, ADLER's Head of Division for the Furniture Industry, tells us: "Companies in the furniture and parquet flooring industries have already started working with board materials that have been printed in a wood design. These surfaces certainly look very natural, but they feel completely smooth. DLE plus makes it possible to create a surface that is true to nature with a wood grain and a pore structure that you can actually feel." Yet aside from the natural wood look, there are almost no limits to what is possible: an authentic stone, concrete or tiled structure can be achieved, as can a playful decorative design. A particular advantage is the huge potential for creating individual designs: "The advantages of modern digital printing mean that even small batch sizes are straightforward to realise; in addition, the DLE system can be integrated into existing coating machinery without any great expense or effort.

Technological expertise

Working in close collaboration with the plant and equipment manufacturer Hymmen, ADLER have expanded their range of UV-curing furniture varnishes and tailored them specifically to this new technology. With Innolux Topcoat DLE, ADLER offers the perfect product for use with the DLE and DLE plus techniques. The varnish performs well as it is reliable and efficient in use and produces an extremely durable surface that is scratch-resistant and chemical-resistant. The pleasant feel of the varnish creates a surface that is just like a natural product. "Issue-free teamwork between coating technology and plant and equipment technology is crucial for industrial users. Our experience with the DLE method and our high level of technological expertise mean that we can offer our customers comprehensive support, enabling them to make optimal use of the diverse range of possibilities offered by DLE and DLE plus.

ADLER – paint runs through our veins

With 670 employees, ADLER is Austria's leading manufacturer of varnishes, paints and wood preservatives. Founded in 1934 by Johann Berghofer, this family business is now managed by a member of the third generation, Andrea Berghofer. Every year, 22,000 tonnes of paint leave the Schwaz plant and are delivered to customers in more than 30 countries worldwide. ADLER has sales subsidiaries in Germany, Italy, Poland, the Netherlands, Switzerland, the Czech Republic and Slovakia; their sole production site is the ADLER-Werk Lackfabrik in Schwaz, Tyrol (Austria). ADLER was one of the first companies in its sector to be 100% climate-neutral (since 2018). The company has been able to reduce its carbon footprint to a minimum through a wide range of measures. ADLER offsets any unavoidable residual emissions through the purchase of recognised climate protection certificates, thereby helping to finance new climate protection projects.

© by adler-lacke.com